Helical gears vs spur gears

When comparing spur and helical gearsets, it is well established that spur gears produce more noise. The difference comes directly from the engagement kinematics between the sun, planets and ring gear.

Both architectures offer advantages depending on the application.

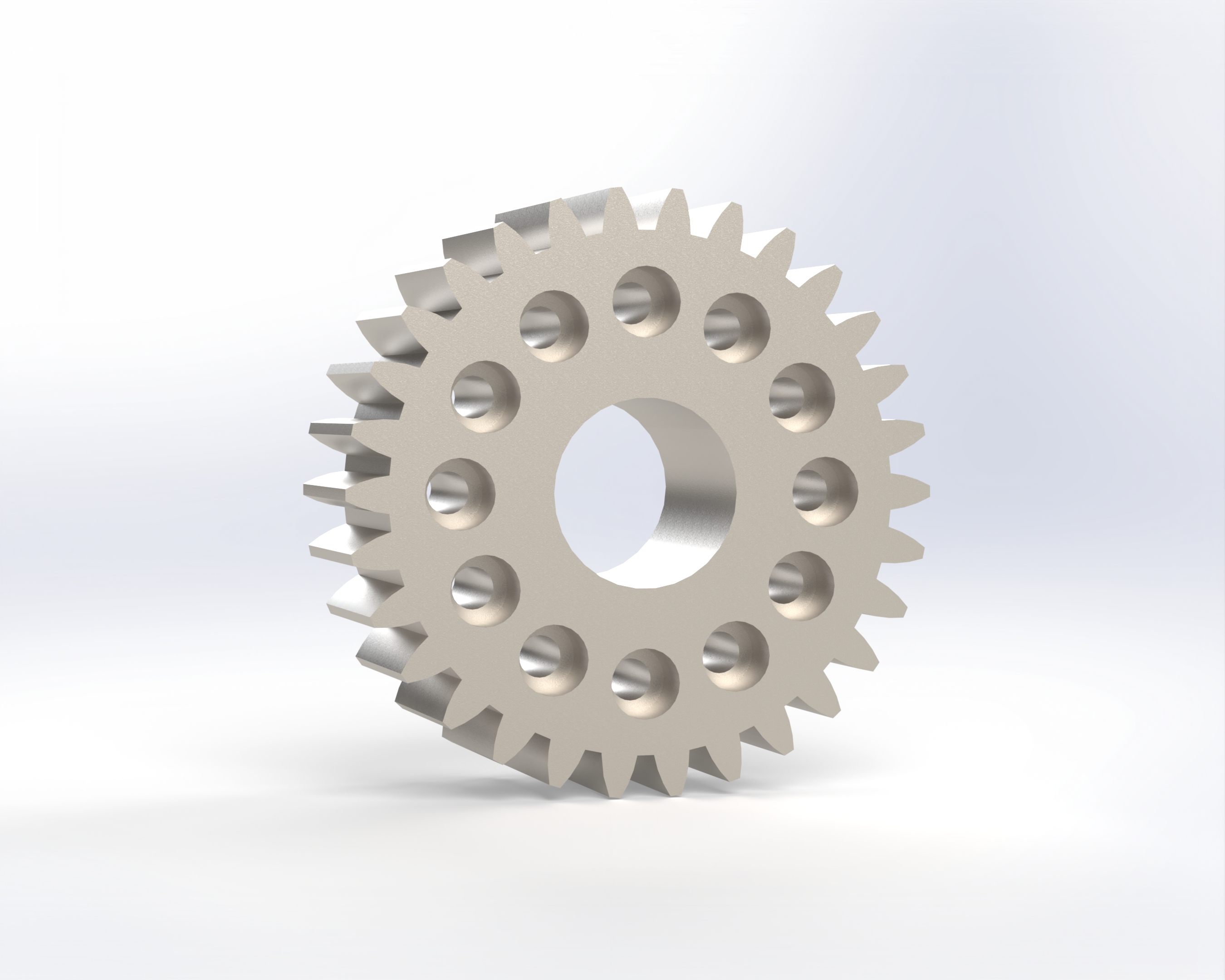

Spur gears: higher noise levels

Spur gears use straight teeth, which enter and exit contact abruptly.

With a typical contact ratio below 2.0, only one tooth (occasionally two) is carrying the load at a given time. This intermittent tooth engagement generates:

-

higher acoustic emissions,

-

more vibration,

-

and a less smooth torque transfer.

In short, lower contact ratio = higher noise.

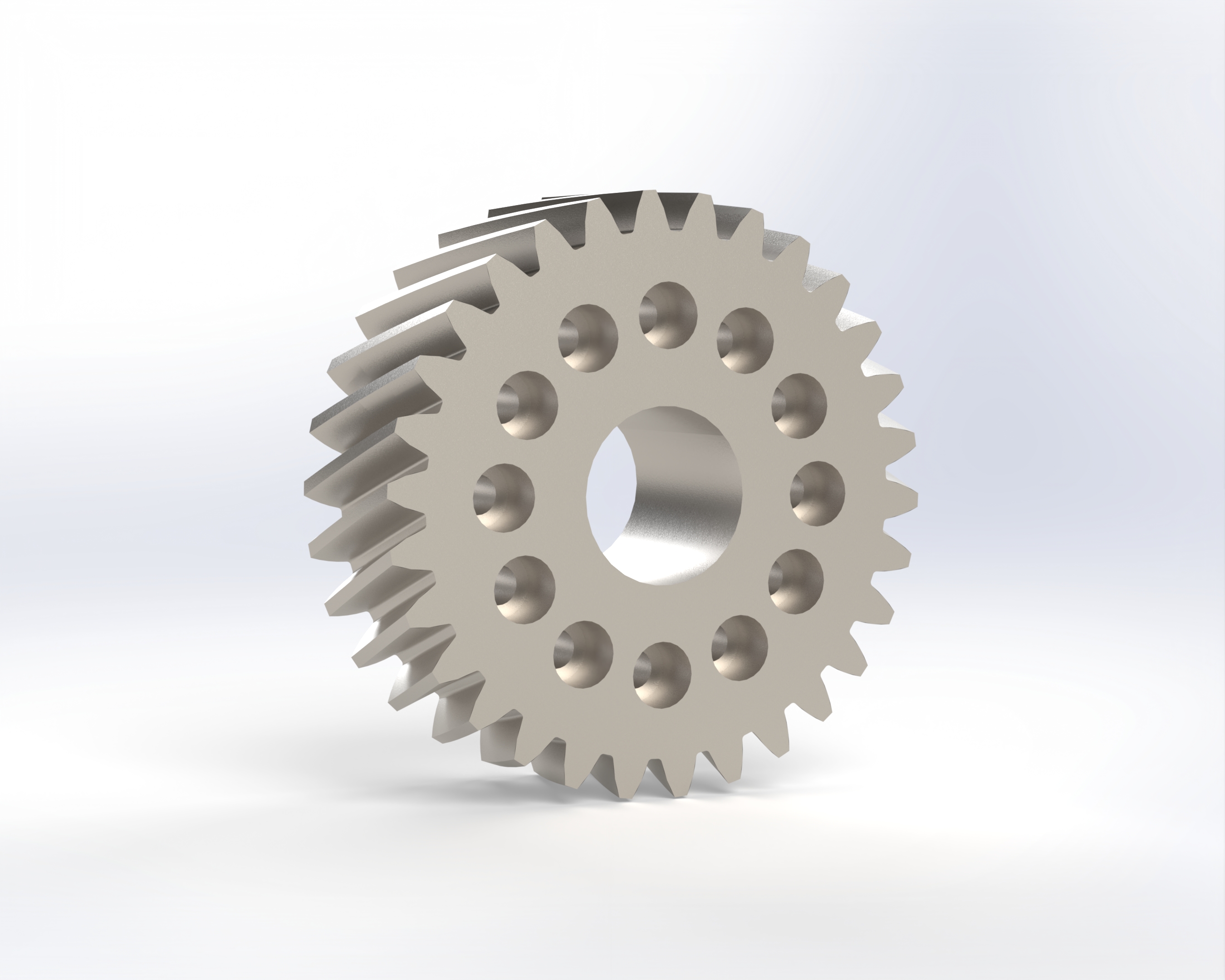

Helical gears: quieter, but with axial forces

The helix angle increases the number of teeth engaged simultaneously, often pushing the contact ratio above 2.0. This produces:

-

smoother torque transmission,

-

reduced vibration,

-

and significantly lower noise.

However, the same helix angle also generates axial forces inside the gearbox. These forces act on bearings, friction disks and structural interfaces.

If not properly absorbed or balanced, these axial loads may reduce the gearbox’s service life.

Choosing the correct output pinion: helical or spur?

A helical output pinion meshing with a rack or another gear creates axial thrust on the gearbox output shaft.

Therefore, we recommend using:

- Helical pinion + helical planetary gearbox, as opposing axial forces from the planetary stage reduce the net load on the bearings.

- Spur pinion + spur planetary gearbox. For straight-tooth internal gearsets (such as Access, Spirit, or Init series), using a spur pinion avoids unnecessary axial loads and maximizes bearing life.