- For 1 stage gearboxes the available ratios are 3, 4, 5, 6, 7, 8, 9 and 10.

- For 2 stages gearboxes, you can order any ratio which is multiple of these. For example you can select a ratio 81 (9x9)

- 3 stages ratios are available too. For example ratio 300 is made of 10x6x5 or 10*10*3

Not all ratios are visible in the datasheets, but they can be done standard. To know what torque can be delivered in the ratio you wish to order, you should know that we always place the highest ratio at the input. For example ratio 35 is made of 7x5 so 7 will be the input ratio and 5 the output ratio. The torque value you are looking for is the torque of ratio 5.

Admissible rated and max torques vary with the reduction ratio. Due to the planetary speed reduction principle, not all ratios are equal, and not all ratios can provide the same performance.

The reduction ratio is the ratio between the number of teeth of the sun gear and the number of teeth of the other internal gears (planet gears and ring gear). In a ratio 10 planetary gearbox, the sun gear will have a small number of teeth and the planet gears will have a large number of teeth. In a ratio 3 gearbox, the sun gear will have a large number of teeth, but the planet gears will be small. This fact has consequences on the best ratio to adopt.

Let's compare the consequences of using a ratio 10 or a ratio 3.

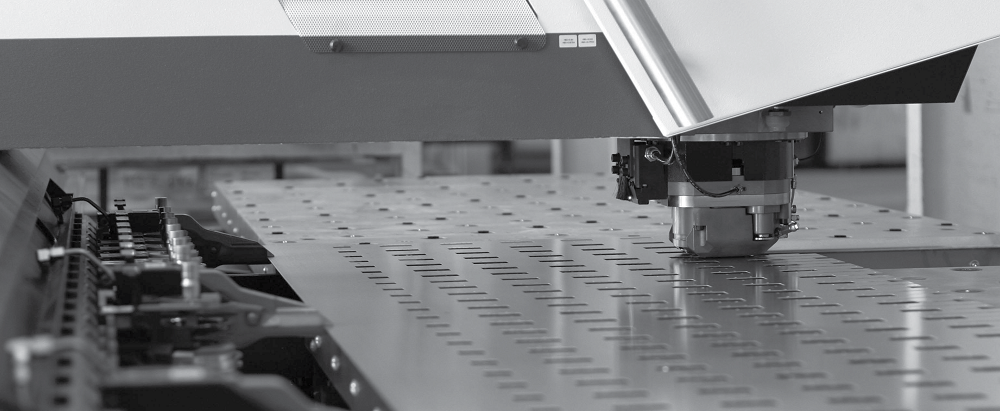

In a ratio 10 (as on picture), only one part will rotate fast: the sun gear. Its size is small compared to the size of the 3 planet gears. Consequently we could say that ratios 10 are ideal when rotating continuous (because the planet gears rotate slowly, temperature won't build-up at the level of the needle bearings inside the planet gears) but ratio 10 will not perform that well in fast reversals conditions (because the sun gear is small and the other elements (like planets or planet carrier) are heavy, it may suffer from faster fatigue damage than other ratios during reversals). Unlike planet gears, the sun gear carries all the power from the motor!

- In a ratio 3, the principle is opposite : the sun gear is large and the planet gears are small and light. The weak element will not be the planets or the sun gear, it will be the inner ring gear, which may suffer from abrasive wear during acceleration. As well, in case of a continuous rotation, the needle bearings inside the planets will rotate fast, possibly leading to excessive temperature.

- It is generally accepted that "strong" ratios are ratios 5 and 6, as they will perform safely both for continuous rotation and for fast reversals applications.

- Ratio 4 will perform well in fast reversals conditions. Both the planet gears and the sun gear will have a large number of teeth.

- Ratio 10 may look convenient to use at first sight, but it is the weakest construction you can get in a single stage planetary gearbox.

If you can modify the number of teeth of your output component (pulley, or pinion when using a rack for example), you may consider adjusting its number of teeth so you obtain a ratio 4 to 8 in the planetary gearbox. 4 to 6 will be preferred when accelerating frequently, 6 to 8 when rotating during a longer period. If you cannot use a ratio 8 instead of a ratio 10, maybe a ratio 12 would fit, and you would enjoy the strength of the ratio 3 or 4 used on its output.

We will be happy to optimize the gearbox internal construction based on your application requirements. For example a ratio 36 can be made of 4x9, or 6x6. We will select 6x6 in case of continuous rotation, or 4x9 in case of fast reversals... if we get the information! So do not hesitate to contact us, we will be happy to help!

Our Polish exclusive distributor WAMEX will be glad to meet you at their stand located Hall B, stand B1.16.

Our exclusive dealer for India, Apex Precision, is happy to invite you to Engimach. Learn how to improve your transmission at stall 1, hall 8

Scan the QR code in this article and use the APEXPREC coupon code for instant privilege access.

Meet with our Italian team! New Reckon products will be displayed on HALL 3 STAND D051