How are lifetime and torque ratings linked in a planetary gearbox?

Face-to-face comparison with competitor’s products is not easy, because there is no standard way of presenting data.

-

For any gearbox, many different ratings could be published, depending on choices made by the engineer calculating them, for instance :

-

Calculating bearings with a slower rotation speed improves the expected lifetime and/or the torque and admissible efforts on shaft,

-

Calculating gearboxes using an L10 life factor (allowing 10% of products to fail before expected lifetime!), or the safety and application factors used when proceeding to the calculation. Results can vary immensely with a similar product.

-

Beware of abnormally high torque ratings as they can be misleading.

-

We do not add an L10 factor to our calculation because it inflates torque ratings artificially and we consider it misleading. Who would accept a 10% failure rate before normal lifetime?

-

Bearing and gear calculation consider rotation speeds, temperature and application factors corresponding to real-life needs.

-

Even so, there is no "ready-to-use" torque data corresponding exactly to the way your application works. Lifetime of a gearbox will greatly depend on the way your application will:

-

wear the surface of the teeth, causing a loss of precision and affecting lifetime (for example when the rated torque is too high compared to nominal torque)

-

bend them too much or too often, potentially leading to fatigue breakage (when the application factor used was not adapted to the gearbox)

-

break them instantly (when a shock occurs) or sometimes weeks after a torque overload

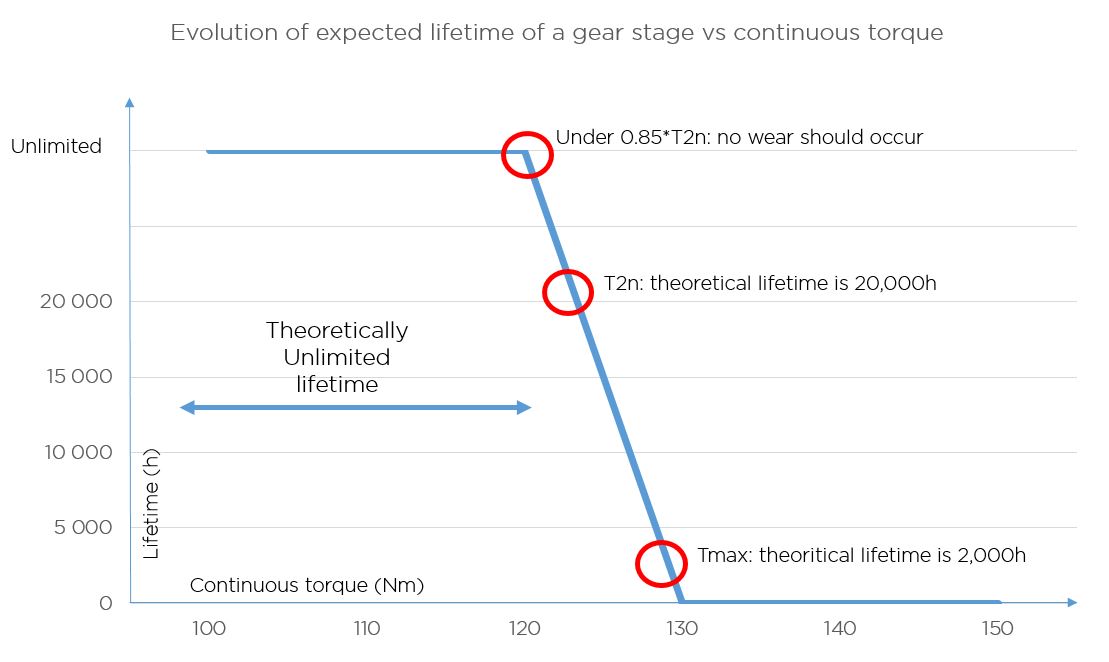

Lifetime of a gear stage is not proportional to the output torque.

When a gearbox is properly dimensioned for an application, the theoretical gearing lifetime is unlimited because the film of lubricant between the gears is protecting them from working "metal-against-metal", and because fatigue breakage will not happen under such conditions if they were calculated right.

At Reckon,

-

Theoretical gearing lifetime is unlimited if your rated torque is 15% under t2n

-

Theoretical gearing lifetime is 20,000h if your rated torque is t2n

-

Acceleration torque can be used 2,000 hours if it is under tmax

The graph below illustrates how lifetime of a gear stage evolves together with the input torque. This graph is for information only, using the ISO 6336-2 calculation methodology, and does not take bearings or seals into consideration.

You may notice how sharp the decrease of lifetime is, after nominal torque is exceeded.

It should be noted that a planetary gearbox’s lifetime depends as well on seals, lubricant or bearings condition, and it can be affected by fast variations of torque or reversals (refer to the "application factors" section).

Reckon's published data results from dedicated software calculation, and products were tested in real-life conditions. We chose to follow the ISO 6336-2 calculation norm, as we consider it is a very safe method (it is used in the gear calculation of European space mechanisms). Our data is conservative, however it is important to note that indicated torque ratings or lifetimes can be affected by different factors:

-

Temperature (calculation was based on a 40°C internal temperature), as lubricant viscosity differs with it. When the gearbox was selected properly, you should not notice more than a 40°C difference with the ambient temperature, and anyway the gearbox body (external housing) should never exceed 90°C.

-

Speed (calculation was based on the rated speed indicated in the product datasheets). Exceeding this speed can increase the internal temperature and be prejudicial to the gears, bearings and seals lifetime. Make sure you do not routinely exceed the nominal speed value. If you need the gearbox to run faster than indicated on the datasheet, do not hesitate to contact us, we can usually modify the input stage so it accepts higher speeds.

-

The Application Factor (see explanations on next pages). This is an empirical value based on experience, and you have to multiply it by your average nominal torque to get your rated torque evaluation.

As a conclusion, any published data should always be considered indicative because the data precisely corresponding to your application just does not exist.

Our engineers will give you an evaluation of your gearbox’s lifetime based on your application's real duty cycle and working conditions, using software calculation.