All our racks are interchangeable with products from competition.

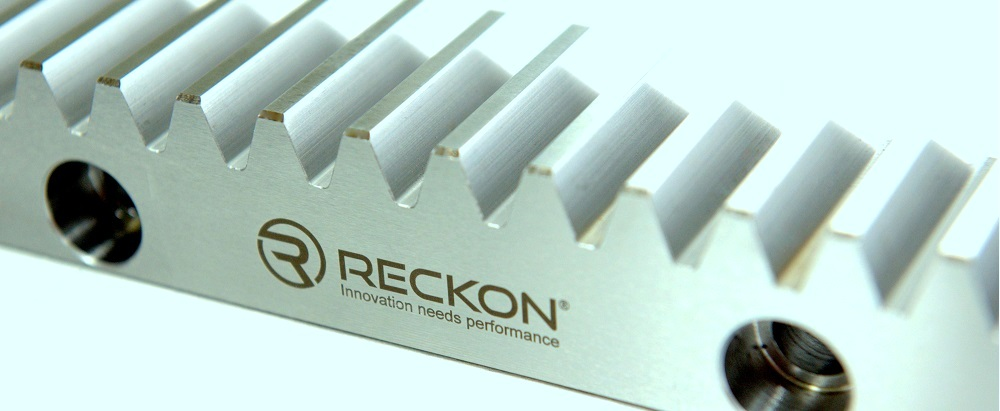

When it comes to rack quality, choosing a Reckon® rack ensures that the following aspects are seriously taken care of:

- Toothing precision is inspected on a CMM with last generation rack-inspection software and our racks are delivered to you with detailed inspection reports showing:

o Flatness

o Straightness

o individual and cumulative pith errors

o the precision of the faces towards teeth and bottom

- Material quality, as Reckon® are made of stabilized material from the best suppliers, so you do not suffer from any low of precision due to residual stress release, or irregular treatment depth.

- Chamfering of every tooth is performed carefully, in order to protect your assembly workers from potentially serious injuries (racks are heavy and they are very sharp before chamfering) and long sick-leaves.

- Heat treatment is carefully checked. We perform regular cut tests after induction hardening and verify the hardness of every batch of steel we get. Our hardness values are conservative so you don’t have a bad surprise.

- Aesthetics are given a very close watch. We are aware that your equipment’s visual quality depends on ours too.

- Packaging will respect all international legal requirements (compatible with wood packing restrictions in international shipping of ocean freight).

- All racks are packed individually and protected with anticorrosive oil.